Microgravity Phase Separators

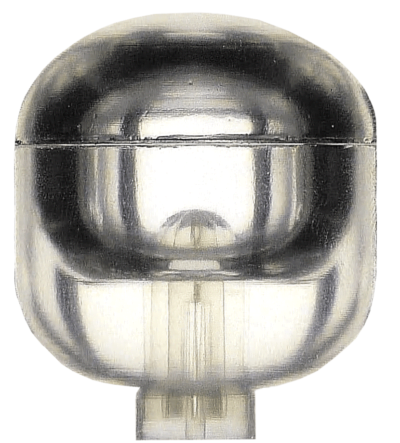

Phase separation in low-g is a necessary function for a variety of systems aboard spacecraft including life support, environmental control, plant habitation, and wet lab operations, to name a few. Our design approach generates passive phase separating solutions by combining geometry, fluid properties, and wetting to preferentially locate and separate phases without moving parts, resulting in reliable and robust solutions. A summary of capabilities include:

Propellant Management Devices

IRPI is experienced in the design, development, and qualification of propellant management and liquid acquisition devices. A summary of capabilities include:

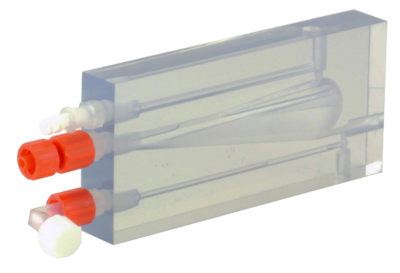

Given volume, flowrate, fluid, and material data we provide the geometric design for propellant management and liquid acquisition devices for in-space transportation. In addition, we are able to demonstrate scaled devices in a drop tower, provide computational results using Surface Evolver, and incorporate self-gravitation for deep space missions.

A scaled liquid acquisition device tested in a drop tower.

Microgravity Wet Lab Hardware

Traditional wet chemistry processes are challenging in a low-gravity environment due to the absence of gravitational forces and buoyancy. As a result, wet lab equipment and processes must be designed to accommodate the microgravity environment through careful design and consideration of fluid properties. Often this includes custom design of components and devices including: